04 Dec, 2025

I. Core Definition

Biological indicators are products containing specific live microorganisms, which usually have known and highly stable resistance to specific sterilization processes. It is specifically designed to verify the sterilization of sterilization equipment (such as high-pressure steam sterilizers, ethylene oxide sterilization cabinets, etc.), the sterilization of specific items, and to evaluate the sterilization effect of isolation systems/sterile clean rooms, in order to verify whether the sterilization process is truly effective.

1. Direct measurement of biocidal effect: Physical and chemical parameters can only prove that the equipment "provides" sterilization conditions, but cannot prove that these conditions "achieve" the expected effect of killing microorganisms. The equipment may have problems such as cold spots and insufficient steam saturation that physical sensors cannot fully reflect. Biological indicators provide biological evidence.

2. Challenge the most extreme situation: The microorganisms in the biological indicator are carefully selected bacterial spores with the strongest resistance to specific sterilization methods. Its death means that all natural pollutants with weaker resistance than it will inevitably be killed.

3. Mandatory requirements of regulations and standards: In the fields of pharmaceuticals, medical devices, etc., the pharmacopoeias of various countries (such as the Chinese Pharmacopoeia and USP) and GMP norms clearly stipulate that biological indicators must be used regularly to verify sterilization processes, identify the purity and morphology of microorganisms, and determine the quantity of microorganisms.

Ii. Constituent Elements of Biological Indicators

A standard biological indicator usually includes:

1. Carrier: An object that carries microorganisms, such as filter paper sheets, stainless steel sheets, glass sheets or the inner surface of ampoules. As shown in the following figure

2. Live microorganisms: This is the core. It is usually the spores of bacteria, as spores are the most resistant form in the living world and have extremely strong tolerance to heat, chemicals and radiation.

3. Common strains:

Bacillus stearothermophilus: Validation for moist heat sterilization (such as high-pressure steam sterilization). Its spores have the strongest resistance to high-temperature saturated steam.

Bacillus subtilis: Validation for ethylene oxide sterilization and dry heat sterilization.

4. Known quantity: The number of viable spores contained in each serving of biological indicator is known and stable, typically ranging from 10⁵ to 10⁶ CFU (colony-forming units). This provides a basis for quantitatively evaluating the sterilization effect.

5. Basic packaging: Protect the carrier and microorganisms, and allow sterilization factors (such as steam and gas) to penetrate. For example, glass ampoules or dedicated paper-plastic bags.

Iii. Retention Conditions of Biological Indicators

Liquid biological indicator: It must be refrigerated at a temperature of 2°C to 8° C. Freezing or violent shaking is strictly prohibited. Store it away from light. Pre-use operation: After taking it out of the refrigerator, it should be left to stand and return to room temperature before use. Shake gently or swirl before use to ensure the spores are evenly suspended.

Paper biological indicator: Refrigerate at 2°C - 8°C. Some products can be stored at room temperature (such as 15-25°C) in a cool and dry place after special stabilization treatment, but refrigeration is still the preferred and most reliable method. Strictly prevent moisture and must be stored in a sealed container in a desiccator. Avoid light. Pre-use operation: After taking it out of the refrigerator, it should be restored to room temperature in a sealed state before opening the package to prevent condensation water from soaking the paper.

Stainless steel plate carrier biological indicator: Refrigerated at 2°C - 8°C. Strictly prevent moisture and must be stored in a sealed container in a desiccator. Avoid light. Pre-use operation: After taking it out of the refrigerator, it should be restored to room temperature in a sealed state before opening the package to prevent condensation water from forming on the cold surface of the steel sheet.

Note: Specific operations must strictly follow the product manual of the biological indicator you are using and the quality management regulations of your institution.

Iv. Inspection Process

1. Liquid biological indicator

Take 4 biological indicators, open them and draw 1ml of each into sterilized glass test tubes. Then add 9ml of the diluted solution. First, heat them in a water bath, then immediately place them in an ice bath for 2 minutes. After taking them out, vortex for 1 minute. Dilute to the required level and add them to petri dishes, then spread and count. The heat shock and culture conditions are shown in the table below. The heat shock and culture conditions are as follows:

|

|

|

| 95-100℃,15 min | 55-60℃,48h |

| 65-70℃,15 min | 30-35℃,48h |

2. Paper carrier biological indicators

Take 4 carriers and place them respectively in 4 sterilized glass test tubes. Add 10ml of dilution solution, then add an appropriate amount of sterilized glass beads. Vortex for an appropriate time until the paper pieces are completely paste-like. First, heat them in a water bath, then immediately place them in an ice bath for 2 minutes. Take them out and vortex for 1 minute. Dilute to the required grade and then add them to petri dishes for coating and counting.

3. Metal strip carrier biological indicator

Take 4 carriers and place them respectively in 4 sterilized glass test tubes. First, add 5ml of dilution solution, then add an appropriate amount of sterilized glass beads. Ultrasonicate for 7 minutes, move the position and continue ultrasonicate for 8 minutes, then add 5ml of dilution solution. This is a 10-fold dilution. After vortexing for 1 minute, first heat it in a water bath for 15 minutes, then immediately place it in an ice bath for 2 minutes. Take it out and vortex for 1 minute. Dilute it to the required grade and add it to a petri dish, then spread and count.

V. Precautions

1.Sample pretreatment: The samples should be placed in an ice bath to maintain a temperature of 0-3℃. Use a glass test tube to hold the sample; In combination with glass beads of approximately 4 to 6 mm in diameter, vortex treatment is carried out at 3000 r/min on a vortexometer. It is recommended to set the ultrasonic conditions at a power of approximately 500 W and a frequency of about 60 Hz.

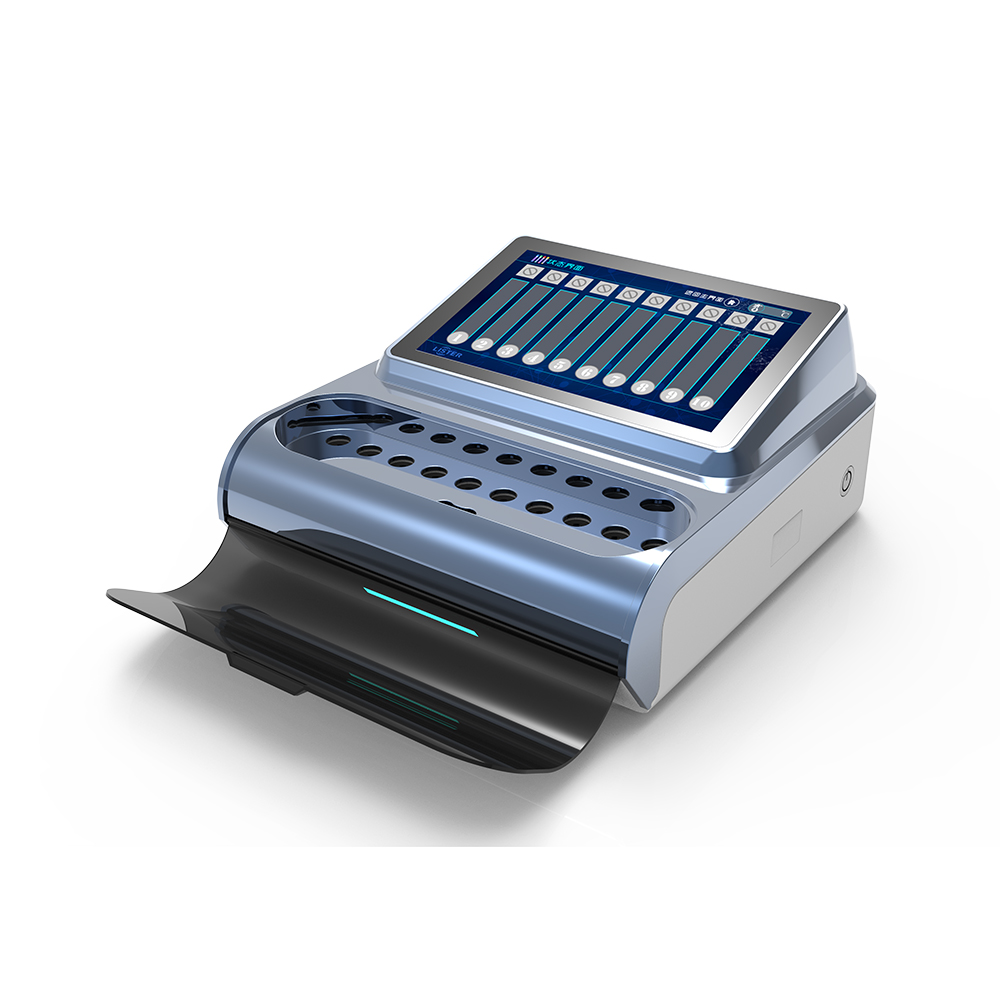

2. Sample holder selection: It is recommended to use a stainless steel holder to place the sample to reduce the absorption and shielding of ultrasonic energy. At the same time, it should be ensured that the bottom of the sample does not come into direct contact with the bottom of the ultrasonic cleaning tank to avoid interfering with the generation of ultrasonic waves by the transducer.

3. Sample placement method: Samples should be evenly and equidistant distributed to avoid uneven sound field distribution in the cleaning tank due to factors such as standing wave formation, sample obstruction, and ultrasonic absorption and attenuation. An excessive number of samples or their disorderly placement will both affect the ultrasonic treatment effect.

4. Liquid level height control: During the processing, it is necessary to ensure that the liquid level fully submerges the sample to guarantee the consistency and sufficiency of the elution effect.

5. Pretreatment of ultrasonic instrument: Before placing the sample, the ultrasonic instrument should be turned on and run unloaded for 5 minutes to exhaust air, so as to eliminate the interference of air bubbles on the transmission of ultrasonic energy.

6. Temperature control: The cavitation effect of ultrasonic waves is best within the range of 35 to 60℃. It is recommended to operate within this temperature range to enhance processing efficiency.

Summary: Biological indicators are simple yet powerful tools that ultimately boil down complex physicochemical parameter verifications to a clear biological problem. It is the last and most crucial line of defense in the aseptic guarantee system, widely used in hospitals, pharmaceuticals, medical devices, food industry and scientific research, etc. It is an indispensable tool for ensuring product safety and public health.

Tags: